Safety systems verification is a stringent testing process that ensures vehicle repairs meet regulatory standards for safety and quality. By rigorously validating components like airbags, brakes, and electronics, car body shops demonstrate compliance, build customer trust, and enhance road safety, all while avoiding legal penalties.

Safety Systems Verification plays a pivotal role in ensuring regulatory repair compliance, particularly within stringent industrial and automotive standards. This process verifies the reliability and functionality of complex safety systems, addressing potential failures before deployment. By systematically evaluating design, development, and implementation, organizations can navigate intricate regulatory requirements effectively. Through comprehensive testing methodologies, verification guarantees that safety mechanisms function as intended, fostering a culture of safety and quality assurance across industries.

- Understanding Safety Systems Verification's Role

- Navigating Regulatory Requirements Effectively

- Ensuring Compliance Through Comprehensive Testing

Understanding Safety Systems Verification's Role

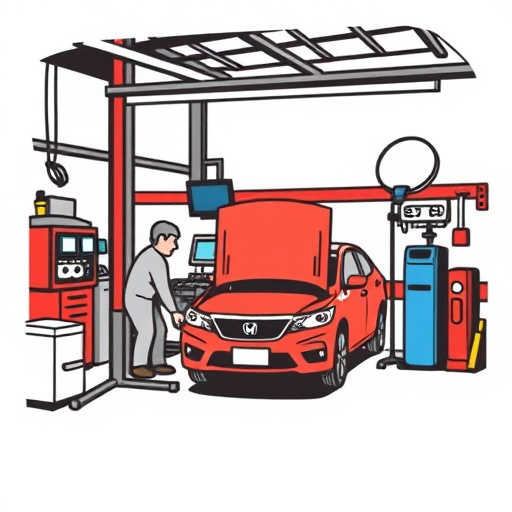

Safety Systems Verification plays a pivotal role in ensuring that vehicles meet stringent regulatory standards. It’s a meticulous process that scrutinizes various safety components within a vehicle, from airbags and seatbelts to anti-lock braking systems and electronic stability control. This thorough verification is not just about checking boxes; it involves rigorous testing and validation to guarantee that each safety system functions optimally under different conditions.

For car body shops and vehicle body shops offering repair services, Safety Systems Verification is more than a regulatory requirement—it’s a cornerstone of quality assurance. By adhering to these standards, body shop services can restore not just the physical integrity but also the safety features of a vehicle, ensuring that every fix aligns with industry benchmarks. This meticulous approach ultimately contributes to enhancing road safety and fostering public trust in the automotive repair sector.

Navigating Regulatory Requirements Effectively

Navigating regulatory requirements effectively is a complex task for any industry, especially automotive sectors focused on safety and quality. Safety systems verification plays a pivotal role in this process by ensuring that vehicle restoration or paint repair processes adhere to stringent standards set forth by governing bodies. This involves rigorous testing and validation of components like brakes, airbags, and electronic systems, guaranteeing their reliable operation under diverse conditions.

By implementing robust safety systems verification protocols, auto painting and vehicle restoration shops can proactively demonstrate compliance with regulatory mandates. This proactive approach not only mitigates the risk of costly penalties but also enhances customer trust by showcasing a commitment to safety and quality across every repair or restoration project.

Ensuring Compliance Through Comprehensive Testing

Ensuring compliance with regulatory standards is non-negotiable for any car repair shop aiming to maintain a good reputation and avoid legal pitfalls. Safety systems verification plays a pivotal role in this process by enabling comprehensive testing of various components within a vehicle. This rigorous testing goes beyond mere visual inspection, delving into the intricate mechanisms that ensure the car body restoration process aligns with safety protocols.

By implementing thorough safety systems verification, dent repair experts can identify potential vulnerabilities or defects that might compromise the integrity of the vehicle during the repair process. This proactive approach guarantees that every aspect of car repair, from structural integrity to electronic systems, meets the required standards. Consequently, it fosters trust among customers who seek reliable and safe car body restoration services.

Safety systems verification plays a pivotal role in ensuring regulatory repair compliance, acting as a robust foundation for navigating complex industry standards. By understanding its crucial functions and implementing comprehensive testing strategies, organizations can effectively meet regulatory demands. This approach not only safeguards public safety but also fosters trust in the reliability of mechanical systems across various sectors.